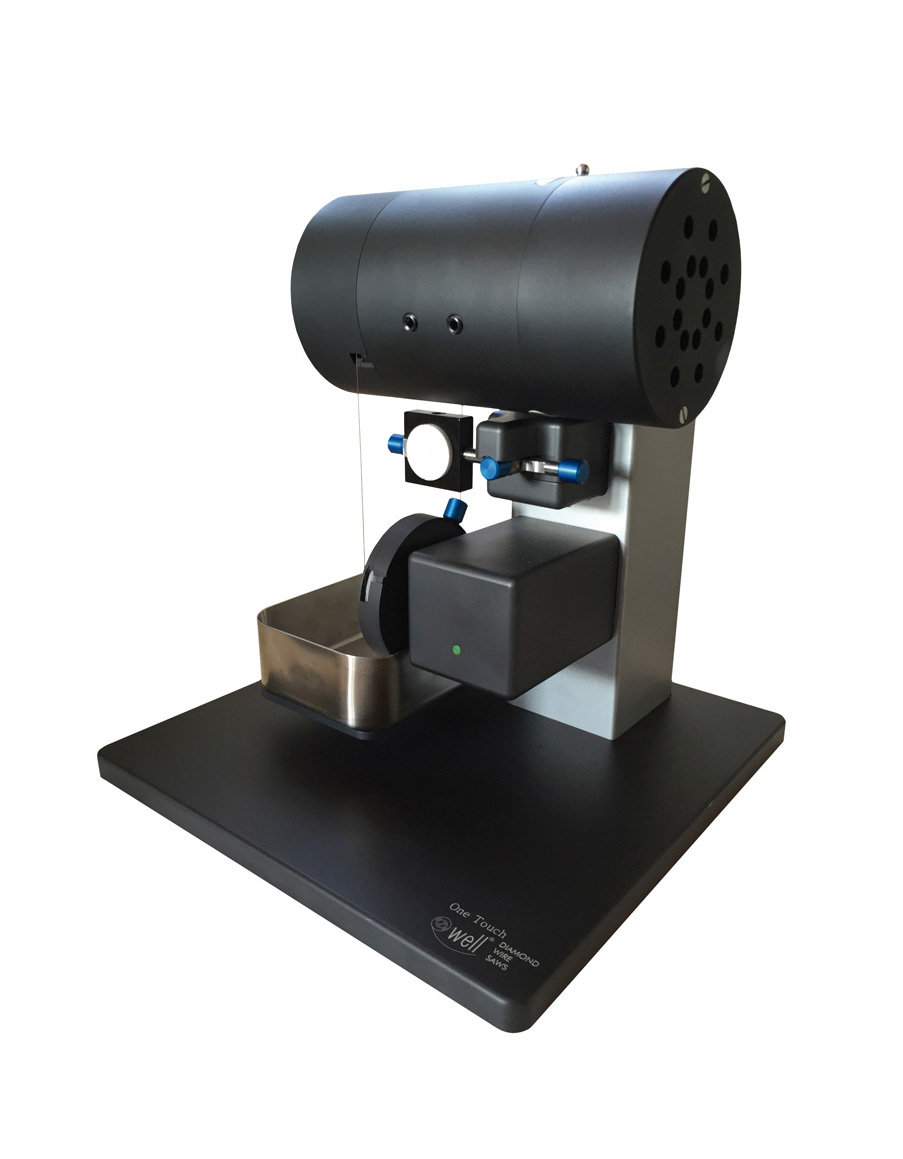

Diamond wire saw series 3000 – High precision cutting

The diamond wire saws of the 3000 series are highly appreciated, especially in laboratories, thanks to their sophisticated design and ease of use. Over 1,800 3000 series saws have been distributed worldwide to date.

This series has been manufactured to industry standard for over 40 years. It is worthy of note that the first machine delivered by Well Diamond Wire Saws SA is still in service today.

The new 3000 series is now available in 3 models (3100, 3400 and 3500). Two versions of the 3500 model are available: a “Base” version and a “Premium” version. Designed to meet market demands, the following features are common to all models:

This series has been manufactured to industry standard for over 40 years. It is worthy of note that the first machine delivered by Well Diamond Wire Saws SA is still in service today.

The new 3000 series is now available in 3 models (3100, 3400 and 3500). Two versions of the 3500 model are available: a “Base” version and a “Premium” version. Designed to meet market demands, the following features are common to all models:

- Variable wire speed control

- Automatic shutdown in case of wire breakage

- 60 mm linear feed

- Sample height adjustment

- Automatic stop at the end of the cut

- Accepts the use of a cutting fluid

Detailed descriptions of the three models are presented below.

The cutting principle of the Well precision diamond wire saw/h2>

All WELL diamond wire saws use a drum with precision threaded grooves machined into the surface to hold the diamond wire in place. The 10-metre-long diamond wire is attached and wound on the drum by a winding device, mounted on a lead screw of the same size as the drum and connected to a motor that rotates in both directions. A loop in the wire is attached to a tensioner pulley to maintain the exact perpendicularity of the cut while moving over the sample. Depending on the model of saw used, the sample can be cut from the inside out or from the outside in. The constant force (feed speed) of the wire against the sample is obtained by gravity. The saw motor housing is guided by precision guides on ball bearings. In addition to the possibility of adjusting the force of the wire, its speed is also adjustable via a continuously variable potentiometer.

Comparative table