A practical, straight, accurate and clear cut with total safety!

Of all WELL saws, the 6500 is without doubt the most versatile. Compact and easy to use, it is suitable for both industrial and laboratory use as it adapts to the most demanding work environments.

Operation of the 6500 diamond wire saw

The renowned WELL cutting principle has been incorporated into the 6500 model, enabling the cutting of quite large samples (300 mm high, 300 mm wide). It has the same design as the 4500 model, but larger.

There is no restriction to the length of the pieces to be cut as long as they can be reasonably placed on the worktable. It is also possible to use the guide pulleys provided with the saw to precisely hold the wire in place.

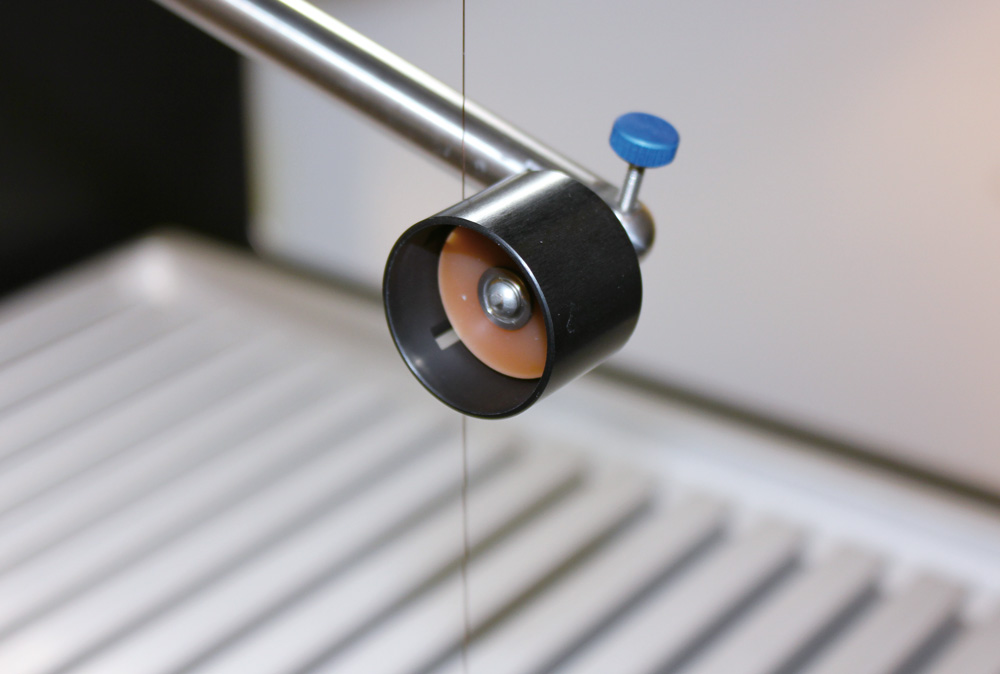

The workpiece must be securely fastened to the work table because the patented 30 m long diamond wire constantly winds and unwinds. The tensioning mechanisms provided with the saw facilitate the tensioning of the wire on the T-slot table. The feed, which operates by gravity, is adjustable between 100 and 1500 g. This relatively low force results in a slightly longer cutting time than the average of the other cutting tools available. However, this process offers undeniable advantages.

It is up to the user to choose between a faster cut that is often more aggressive for materials and the slightly longer but more precise WELL process.

Ergonomic and safe

Although the wire can reach a speed of 2.5 m / s, accidental or intentional contact with the moving wire does not cause injury. It is possible to observe the cutting process at any time from a comfortable distance without being hampered by a cumbersome protective cover. Due to the relatively low forces in action during cutting, it is quite simple to attach the workpieces. If the wire breaks, the saw stops automatically.

A saw for samples of all sizes

To cut small samples, it is possible to use and adjust the auxiliary guide pulleys. The depth of cut is 300 mm. The sample can have a maximum height of 300 mm. It is often clamped onto a grooved table or mounted on a micrometer table to perform parallel cuts.

The grooved table moves without friction on two precision rails. The feed and cutting force are provided by a system of weights. The sample is placed in front of the wire or inside the loop for better visualisation of the cut.

The precision of this cutting method can often save laborious and costly polishing.

Parameters of the WELL 6500 saw

Various adaptable holding accessories are provided as standard or can be made on request. There are different versions depending on the required applications (remote controls, large grooved table, large depth of cut, rotational cut, etc.).

For cutting precise slices, the saw can be delivered with a micrometer table.

Available in a floor (with adapted furniture) and benchtop version, the 6500 can accommodate larger workpieces up to 300 mm high and 300 mm deep and weighing up to 20 kg (approx. 44 lbs). Wire tension is possible up to 20 kg (about 44 lbs).

The advantages of the WELL 6500 diamond wire saw

- The WELL 6500 saw for medium-sized workpieces

- Robust construction for sawing workpieces up to 20 kg

- Maximum depth and height of the cut: 300 mm.

- Diamond wire of Ø 0.13 mm 10 μ to 0.50 mm 64μ or Ø 0.35 mm 64 μ are available.

- Wire speed can be continuously adjusted from 0 to 2.5 m / s.

The technical characteristics of WELL 6500 saws

- Vertical design

- Primary: 230 V / 110 V – 50/60 Hz

- Secondary: 24 V/48 V

- Motor: 240 W

- Control: electronic control

- Speed: 0 to 2.5 m / s

- Wire tension: adjustable / measurable

- Feed: gravity

- Ø drum: 308 mm

- Wire length: 30 m

- Wire diameter: 0.13 to 0.50 mm

- Max. sample weight: 20 kg

- Micrometer table travel: 100 mm

- L x W x H: 650 x 480 x 1200 mm

- Weight: 105 Kg