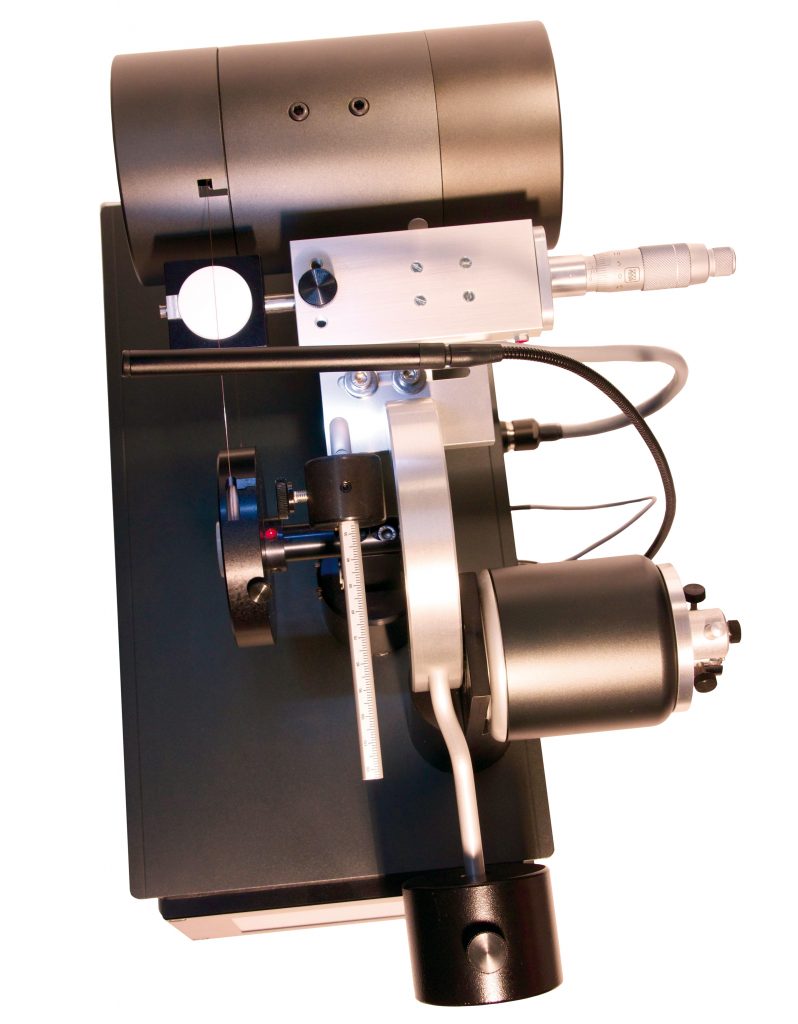

Model 3400 horizontal precision diamond wire saw

As its name suggests, the 3400 enables cutting with a horizontal wire.

This model enables you to cut small workpieces (monocrystalline, semiconductor, ceramic, fragile materials, etc.).

The piece to be cut can be positioned inside the loop, which allows very precise positioning before starting the cutting process, as well as visual monitoring of the piece during cutting. The support for the workpiece is fixed to a beam with a counterweight. This ensures and maintains the required force for the entire duration of the cut. The wire tension is always adjustable using weights.

Operation of the WELL 3400 diamond wire saw

The sample holder is attached to a counterbalanced arm that uses weights to establish and maintain the necessary force throughout the cut or slice. The cutting pressure of the sample on the wire can be adjusted to the nearest gram. Wire tension is also ensured by weights. This saw enables the use of particularly fine diameter wire (up to 0.08 mm). Very often, users choose to mount a microscope on the saw to be able to position the diamond wire with greater accuracy or to observe the cut or slice in progress. A precision micrometer is provided as standard to facilitate fast and accurate sample positioning.

Like the 3500 model, the sample is located inside the wire loop and the progress of the cut can be observed with a microscope.

The advantages of WELL 3400 diamond wire saws

- Horizontal wire

- Continuously adjustable wire speed

- The saw stops automatically at the end of the cut or in case of wire breakage

- Ease of use

- Long duration thanks to an improved design

- 12-month guarantee

- Easy visualisation of the cutting point

- Low-volume cleaning tray

- Low maintenance

- Optimal sample positioning

- Micrometer table is standard

- Easy handling

Specifications of WELL 3400 saws

L x l x h : 450 x 320 x 310mm

Weight : 17 kg

- Ø of the wire and grain :

Ø 0,10 mm – 10 mµ

Ø 0,13 mm – 10 mµ, 20 mµ

Ø 0,17 mm – 20 mµ, 30 mµ

Ø 0,22 mm – 20 mµ, 30 mµ, 40 mµ

Ø 0,30 mm – 20 mµ, 30 mµ, 40 mµ, 60 mµ - Available lengths : 60 m and 120 m

- Other lengths on request

The saw can be fitted with a stereo microscope or viewfinder for accurate positioning of the wire on the cut. A turntable, double vice, sample holder for round workpieces, and single-, double- or triple-axis goniometers are also available.